In modern business, data centers are considered their backbone. They stay open 24/7, act as support for highly critical applications, and store sensitive information. Data centers are set up with the latest infrastructure: redundant power supplies, sophisticated cooling mechanics, and around-the-clock monitoring systems; however, they are not afforded an insurance policy against failure. Surprisingly, from time to time, the reasons climb up its stairs: corrosion.

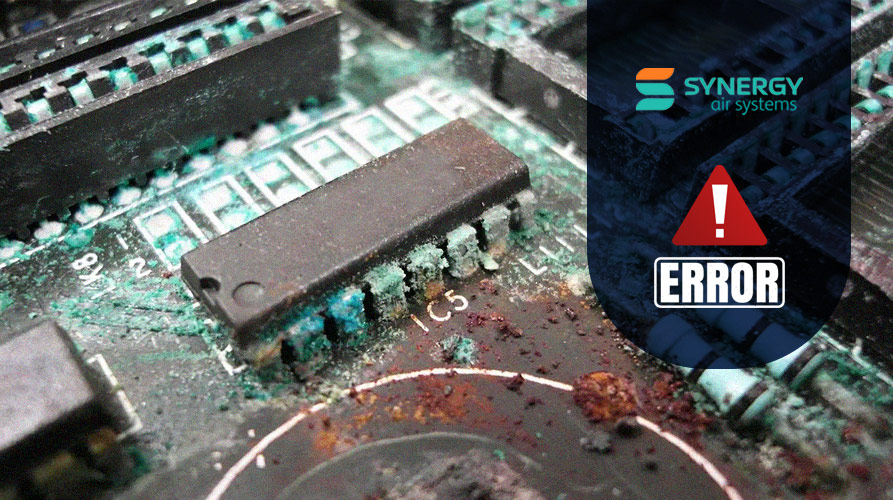

Corrosion control in electronic devices in a data center in vital to stop silent degeneration of servers, switches and circuit boards. If this threat is ignored, it may lead to costly downtime, frequent maintenance and reduced lifespan of machinery.

The Silent Threat: Corrosion

Corrosion doesn’t announce itself. It gradually attracts electronic components through trace gases, humidity and chemical contaminants.

- Cause: Sulfur, chlorine and other pollutants infiltrate data centers through air handling systems.

- Effect: These substances react with metals like copper and silver, degrading connections.

- Outcome: Even minor corrosion can disrupt server communication, cause system error, or trigger cascading failures.

Without preventive corrosion control measures for electronics in data centers, these problems often remain invisible until costly failures occur.

Why Data Centers Are Especially Vulnerable

Data centers face unique challenges:

- Continuous Operation: Servers and network devices are constantly running, making components more susceptible to degradation.

- Air Intake Vulnerabilities: Trace gases and pollutants can enter the facility, reaching sensitive electronics. Gas-phase corrosion control for electronic systems is essential to prevent exposure.

- Humidity Fluctuations: Seasonal changes or cooling system variations can create condensation, accelerating corrosion.

- Standard Filtration Limitations: Dust filters handle particles but cannot neutralize corrosive gases, leaving electronics at risk.

Logical conclusion: any data center lacking corrosion control solutions for electronic devices exposes itself to preventable operational failures.

Real Case Example: Hyderabad Data Center

A Hyderabad data center study highlighted environmental vulnerabilities:

- While the high pollution season sees PM2.5 levels exceed the safe limit quite often,

- Humidity level fluctuations created an ambiance conducive to condensation during the monsoon period, thus raising corrosion risks.

- Standard filtration systems had been able to remove particulates in working order but remained frail when confronted with periodic increases in humidity or pollutant gases.

Recommendation: Install gas-phase filtration systems to control corrosion in electronic equipment, and practice active environmental monitoring. This will protect the more silent degradation of servers, circuit boards, and critical infrastructure.

Gas-Phase Filtration: The Logical Defense

Gas-phase filtration removes corrosive gases from the environment before they reach electronic components. Unlike standards filters, it neutralizes harmful chemicals at the molecular level.

- Purpose: Prevent contact between corrosive compounds and metal surfaces.

- Result: Reduces corrosion-induced failures in servers, switches and circuit boards.

Implementing advanced corrosion control solutions for electronic systems ensures data centers operate reliably.

Consequences of Neglecting Corrosion

Ignoring corrosion control introduces clear risks:

- Unexpected downtime due to degraded connections.

- Increased maintenance and replacement costs.

- Reduced lifespan of servers and networking equipment.

- Operational instability affecting business continuity.

Preventive corrosion control measures for electronics in data centers directly mitigate these risks.

Benefits of Proactive Corrosion Control

Investing in corrosion control yields tangible benefits:

- Extended Hardware Life: Servers, connectors, and circuit boards experience extended performance for an optimal time.

- Lesser Maintenance Costs: Fewer repairs and replacements.

- Better Reliability: Lesser unplanned downtime and predictable operations.

- Peace of Mind: Facility managers can think strategy instead of emergency maintenance.

Logical Observation: Gas-phase corrosion control for electronic systems takes what is hidden hazard and turns it into a preventable risk.

Recommended Action

Data centers are critical infrastructure — leaving electronics exposed to corrosion is a risk no operator should take. Integrating corrosion control in electronic systems, along with gas-phase filtration and active monitoring, ensures:

- Reduced failure incidents

- Extended equipment lifespan

- Operational efficiency

- Protection of business reputation

Proactive corrosion management is no longer optional; it is a necessity.

FAQs

Q.1: What is corrosion control in electronic systems?

A.1: It’s a strategy to prevent chemical reactions that degrade electronic components over time.

Q.2: Why are data centers particularly vulnerable?

A.2: Continuous operation, trace gas exposure, and humidity fluctuations increase corrosion risk.

Q.3: How does gas-phase filtration prevent corrosion?

A.3: It removes harmful gases before they contact servers, circuit boards, and connectors.

Q.4: Are standard dust filters enough?

A.4: No. Dust filters trap particles but cannot neutralize corrosive gases.

Q.5: What are the consequences of ignoring corrosion control?

A.5: Increased downtime, higher maintenance costs, shorter equipment lifespan, and operational instability.